Silicon Carbide Grinding Barrels: Precision, Durability, and Performance for Industrial Application

**Silicon Carbide Grinding Barrels: Precision, Durability, and Performance for Industrial Applications**

**Introduction**

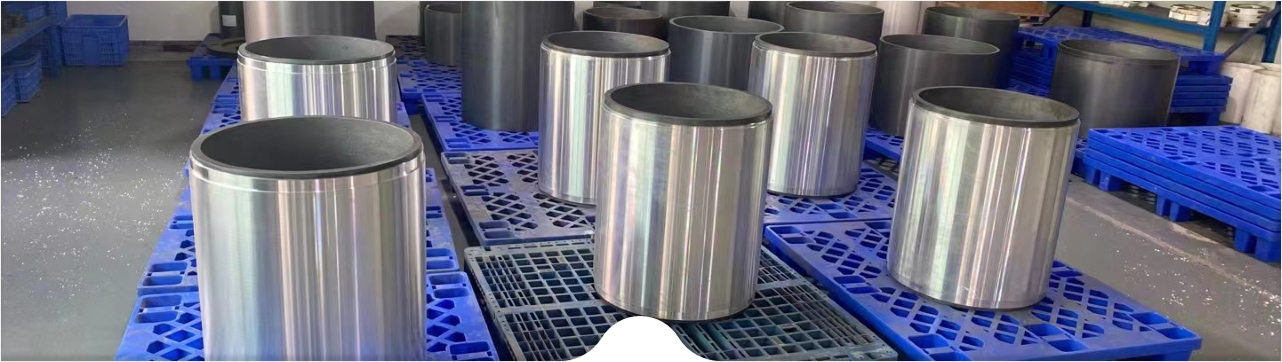

Discover the ultimate solution for high-performance grinding with **silicon carbide (SiC) grinding barrels**—engineered to deliver unmatched precision, durability, and efficiency across industries. As a leading Chinese manufacturer, we specialize in producing **custom silicon carbide grinding barrels** using advanced materials like **reaction-bonded SiC (RBSiC)** and **pressureless-sintered SiC (SSiC)**, ensuring superior performance in extreme environments.

**Why Choose Silicon Carbide Grinding Barrels?**

1. **Exceptional Material Properties**

- **Extreme Hardness**: With a Mohs hardness of 9.5, our SiC barrels resist wear and abrasion, outperforming traditional materials like ceramic or steel by **5–10 times** .

- **High Thermal Conductivity**: Efficient heat dissipation allows operation at temperatures up to **1,650°C**, critical for applications in **semiconductor manufacturing** and **high-temperature processing** .

- **Corrosion Resistance**: Chemically inert to acids, alkalis, and solvents, ideal for **pharmaceutical**, **petrochemical**, and **wastewater treatment** industries.

- **Low Friction Coefficient**: Reduces energy consumption and extends the lifespan of grinding media.

2. **Precision Engineering**

- **Tight Tolerances**: Machined to ±0.001mm for **consistent particle size distribution** in **nano-grinding** and **ultrafine milling** .

- **Customizable Designs**: Available in **various sizes**, **shapes**, and **coatings** (e.g., diamond-like carbon) to meet specific OEM requirements.

- **ISO 9001 & ISO 14001 Compliance**: Adherence to global quality and environmental standards ensures reliability and sustainability.

3. **Applications Across Industries**

- **Ceramics & Glass**: Ideal for **slurry preparation** and **powder mixing**.

- **Electronics**: Used in **wafer processing** and **semiconductor cleaning** to prevent contamination.

- **New Energy**: Enhances efficiency in **lithium-ion battery production** and **photovoltaic cell manufacturing** .

- **Mining & Minerals**: Optimizes **ore processing** and **mineral beneficiation**.

- **Chemical Processing**: Handles **corrosive slurries** and **high-viscosity materials**.

**Key Features**

- **Energy Efficiency**: Reduces power consumption by **30%** compared to traditional grinding equipment .

- **Longevity**: Minimizes downtime with a service life **5–10 times longer** than conventional materials .

- **Contamination Control**: Ultra-smooth surfaces prevent material adhesion, ensuring **hygienic grinding** for food and pharmaceutical applications.

**SEO Keywords**

**Primary Keywords**:

- Silicon carbide grinding barrels

- SiC grinding vessels

- High-precision grinding containers

- Industrial grinding solutions

- Reaction-bonded SiC (RBSiC) barrels

- Pressureless-sintered SiC (SSiC) barrels

**Long-Tail Keywords**:

- Abrasion-resistant silicon carbide grinding barrels

- High-temperature grinding containers

- Custom silicon carbide grinding barrels

- Nano-grinding applications with SiC barrels

- ISO-certified silicon carbide grinding equipment

- Wet grinding solutions with silicon carbide

**Why Partner with Us?**

- **Global Expertise**: Exporting to **30+ countries**, including the US, Europe, and Asia-Pacific.

- **Technical Support**: In-house engineers provide **application-specific solutions** and **failure analysis**.

- **Cost-Effective**: Vertical integration in raw material production ensures competitive pricing without compromising quality.

**Case Study**

A leading **lithium-ion battery manufacturer** achieved a **150% increase in grinding efficiency** and **30% reduction in energy costs** by switching to our **SSiC grinding barrels** for electrode slurry processing .

**Conclusion**

Elevate your grinding processes with **silicon carbide grinding barrels**—the benchmark for precision, durability, and innovation. Contact us today to explore how our solutions can optimize your industrial operations.

---

**Call to Action**:

- Visit www.atceram.com for detailed product specifications.

- Request a quote for **custom silicon carbide grinding barrels**.

- Follow us on LinkedIn for industry insights and updates.

**Meta Description**:

"Discover high-precision silicon carbide grinding barrels for extreme environments. Durable, corrosion-resistant, and ISO-certified—ideal for ceramics, electronics, and new energy industries. Contact us for custom solutions."